Product Description

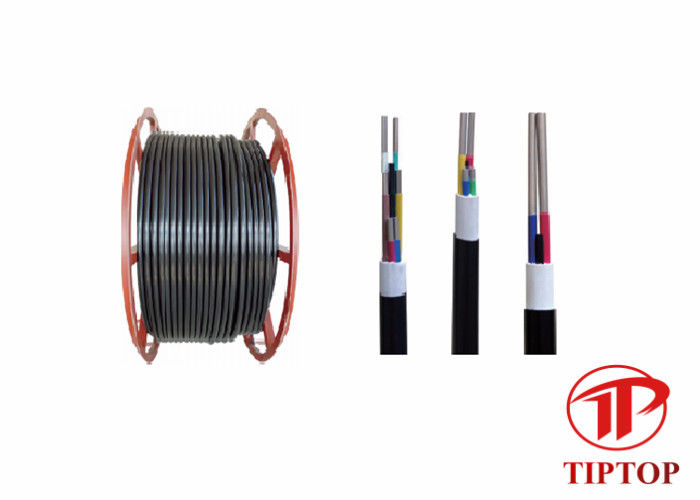

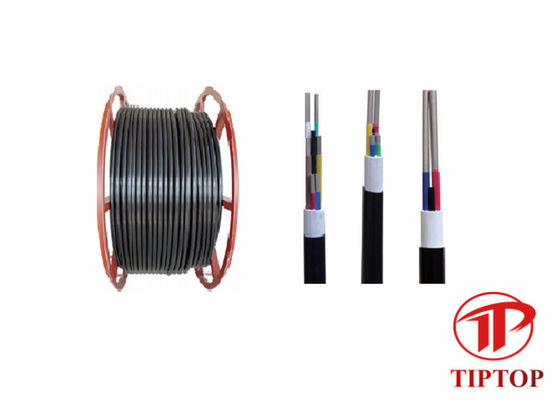

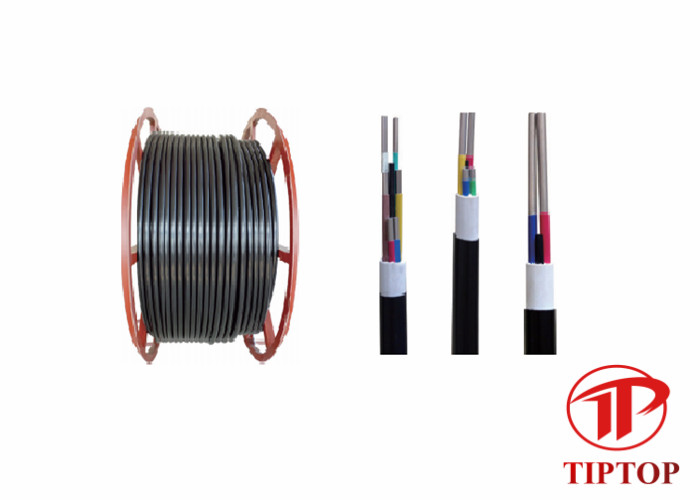

ASTM A269 PVC Covered stailess steel welded multi - core coiled tubing

Introduction:

The stainless steel multi-core tube looks like a cable and is made up of two or more stainless steel seamless single-core tubes or welded single-core tubes.

The products are made of high quality stainless steel raw materials and jackets and fillers produced in accordance with ROHS environmental protection directives.lt has the characteristics of pressure resistance, wear resistance, corrosion resistance, anti-aging, flame retardant and environmental protection.

It is suitable for a variety of harsh climatic conditions and has a high safety factor. It is widely used in remote control and monitoring systems such as shipbuilding, offshore platforms, petrochemicals, power generation, pneumatic.

Features:

1.Easy to lay, labor saving

Multi-core tube is easy to take shape like cables, the operating tools are simple and it is convenient for laying. Mark can be made meter by meter. Each tube has PVC sheath with different colors, which is easy to identify.

2.Superior performance, free of maintenance

Multi-core tube adopts high quality stainless steel strip and outer sheath raw materials produced according to ROHS environmental protection directives, so it is pressure resistant, wear resistant, water and oil-proof, corrosion resistant and aging resistant and can adapt to various complicated climate conditions. It has high thermal resistance, small heat waste and high safety factors, so it will not cause scalding.

3.Customized to avoid waste

Single ultra-long tube can be manufactured based on fixed dimension and multi-core cables can also be manufactured to form one tube and multi-circuit control, thus saving expensive joint and accessories expenses.

4.Positioned as high quality products to ensure absolutely safe

By using high quality raw materials, automatic production process, strict process control and testing means, the hidden trouble of quality can be effectively eliminated.

5.High-tech technology and extensive applications

Multi-core tube is safe, reliable, convenient for laying, occupies little space, easy to configure and convenient for management. It is particularly suitable for pneumatic and hydraulic control system as well as measuring and monitoring system, etc. in the shipbuilding, oil and gas, hydraulic, chemical and other industries.

Specification:

| Material of Tube |

Tube OD |

Wall Thickness |

Cores |

Standard Length of Tube |

| ASTM TP 304/304L/316/316L |

6/8/10/12/14/15mm |

0.8/1.0/1.2/1.5/2.0mm |

1~6core |

Seamless |

Welded |

| 50〜160 |

200〜800 |

Maximum Allowable Working Pressure:

O.D

(mm) |

Wall Thickness (mm) |

| 0.5 |

0.8 |

1 |

1.2 |

1.5 |

2 |

| 6mm |

18.2 |

29.2 |

— |

— |

— |

— |

| 8mm |

13.7 |

21.9 |

27.3 |

— |

— |

— |

| 10mm |

— |

17.5 |

21.9 |

26.2 |

32.8 |

— |

| 12mm |

— |

— |

18.2 |

21.9 |

27.3 |

— |

| 14mm |

— |

— |

— |

18.7 |

23.4 |

31.2 |

| 15mm |

— |

— |

— |

— |

21.9 |

29.2 |

Technical parameters:

|

O.D

(mm)

|

No.of Cores |

Sheath Thickness (mm) |

Overall Diameter (Approx, mm) |

Bending Radius (Minimum mm) |

Weight/kg/m |

| 0.18 |

1.0 |

1.2 |

1.5 |

2.0 |

| 6 |

1 |

1 |

8 |

64 |

0.18 |

0.21 |

一 |

一 |

|

| 2 |

2 |

19 |

152 |

0.67 |

0.71 |

一 |

一 |

|

| 4 |

2 |

23 |

184 |

0.96 |

1.04 |

一 |

一 |

|

| 6 |

2 |

28 |

224 |

1.25 |

1.38 |

一 |

一 |

|

| 8 |

1 |

1 |

10 |

80 |

0.25 |

0.28 |

0.31 |

一 |

|

| 2 |

2 |

23 |

192 |

0.83 |

0.89 |

0.95 |

一 |

|

| 4 |

2 |

28 |

224 |

1.2 |

1.33 |

1.45 |

一 |

|

| 6 |

2 |

33 |

272 |

1.82 |

2 |

2.17 |

一 |

|

| 10 |

1 |

1 |

12 |

96 |

0.3 |

0.34 |

0.38 |

0.43 |

|

| 2 |

2 |

28 |

224 |

1.1 |

1.18 |

1.26 |

1.37 |

|

| 4 |

2 |

34 |

272 |

1.8 |

1.97 |

2.13 |

2.35 |

|

| 6 |

2 |

39 |

320 |

2.15 |

2.4 |

2.63 |

2.96 |

|

| 12 |

1 |

1 |

14 |

112 |

- |

0.41 |

0.45 |

0.53 |

|

| 2 |

2 |

34 |

272 |

- |

1.38 |

1.48 |

1.62 |

|

| 4 |

2 |

39 |

312 |

- |

2.37 |

2.57 |

2.85 |

|

| 6 |

2 |

48 |

384 |

- |

3 |

3.29 |

3.71 |

|

| 14 |

1 |

1 |

16 |

128 |

- |

一 |

一 |

0.61 |

0.74 |

| 2 |

2 |

39 |

312 |

- |

一 |

一 |

3 |

3.26 |

| 15 |

1 |

1 |

17 |

136 |

一 |

一 |

一 |

0.64 |

0.79 |

| 2 |

2 |

39 |

312 |

- |

一 |

一 |

3.08 |

3.36 |

GB/T 12771 Welded stainless steel pipes for liquid delivery

GB/T 3280 Cold rolled stainless steel plate, sheet and strip

GB/T 14976 Seamless stainless steel pipes for fluid transport

ASTM A269/A269M Standard Specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service

ASTM A312/A312M Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes

GB/T 7735 Steel tubes—The inspection method on eddy current test

GB/T 241 Metal materials—Tube—Hydrostatic Pressure test

GB/T 244 Metal materials—Tube—Bend test

GB/T 246 Metal materials—Tube—Flattening test

GB/T 228.1Metallic materials—Tensile testing

GB/T 2406.2Plastics determination of burning behavior by oxygen index—Part 2: Ambient temperature test

GB/T 8815 Plasticized polyvinyl chloride (PVC) compounds for wire and cable

GB/T 18380.12/IEC60332-1-2 Test on electric and optical fibre cables underfire conditions—Prat 12: Test for vertical flame propagation for a single insulated wire or cable—Procedure for 1kw pre-mixed flame

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!